The Beer Game

MIT Supply Chain Management Simulation

Simulation Overview

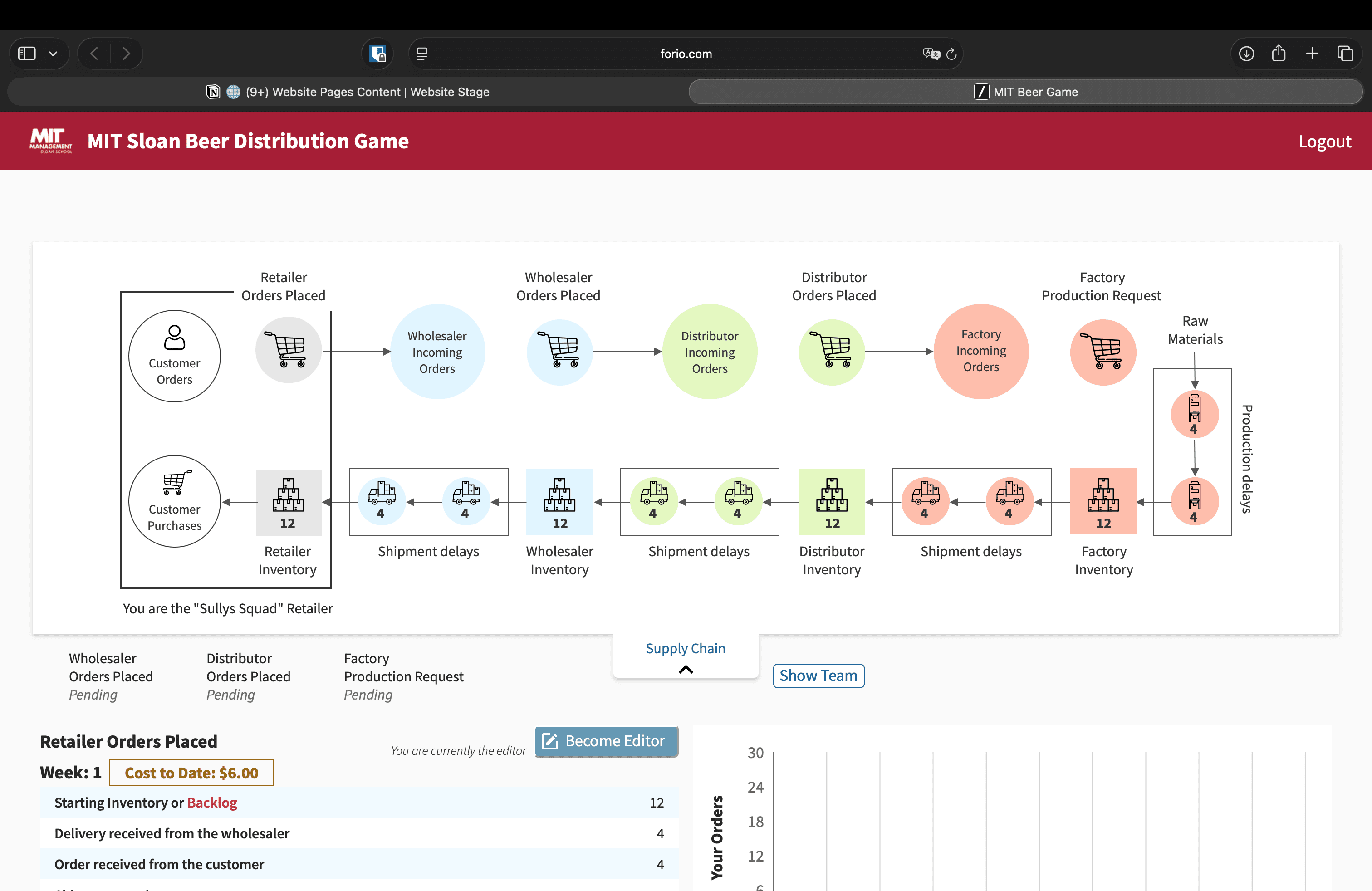

Developed in partnership with MIT professor John Sterman, The Beer Game is one of the most widely used supply chain management simulations. Play one of four positions in a dynamic supply chain for beer distribution as you and your colleagues manage the incoming and outgoing supply.

Each role can influence the entire chain by ordering too much or too little. Often called the “bullwhip effect,” this error can worsen shortages and overstock and wreak havoc on supply chains.

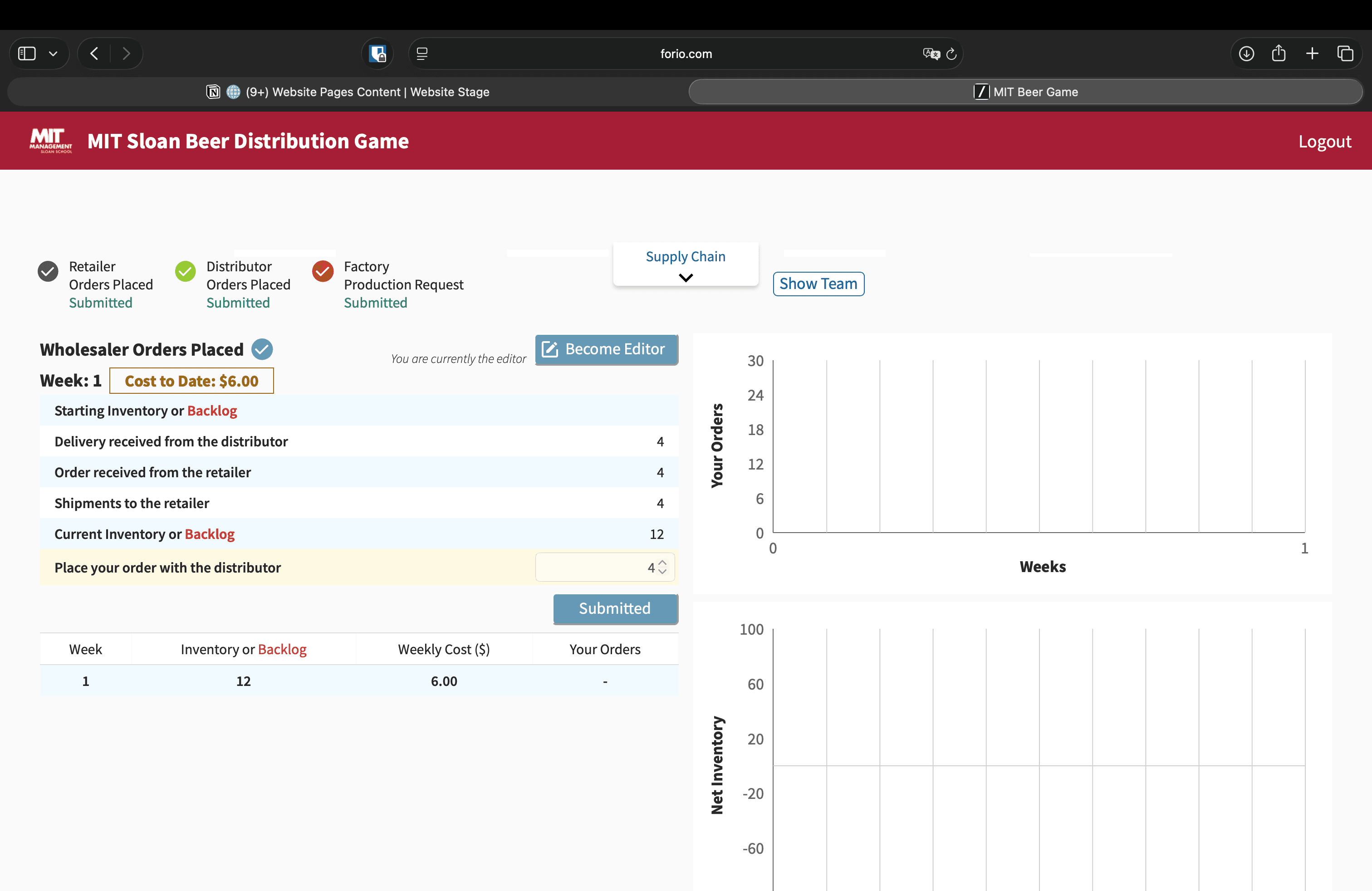

When things go wrong, we often look for scapegoats. The Beer Game simulation addresses the often erroneous, negative attributions we make about others, how they erode trust in organizations, and what can be done to overcome these self-reinforcing beliefs. It’s not bad apples, it’s bad barrels.

Players

Multiplayer

Languages

English

Simulation Time

Total Time: 1.75-2.75 hours

Intro 15 minutes, Gameplay 1-1.5 hours, Debrief 30-60 minutes

Accessibility

WCAG 2.0 Compliance

Price

$165 per person

Simulation Categories

The Story

At Sloan Lager Brewing Co., demand is booming. Customers are thirsty, the product is beloved, and the team is confident. But behind the scenes, the supply chain is far from stable. Small missteps ripple unpredictably from retailer to wholesaler to distributor to factory—creating shortages, backlogs, stockpiles, and frustration.

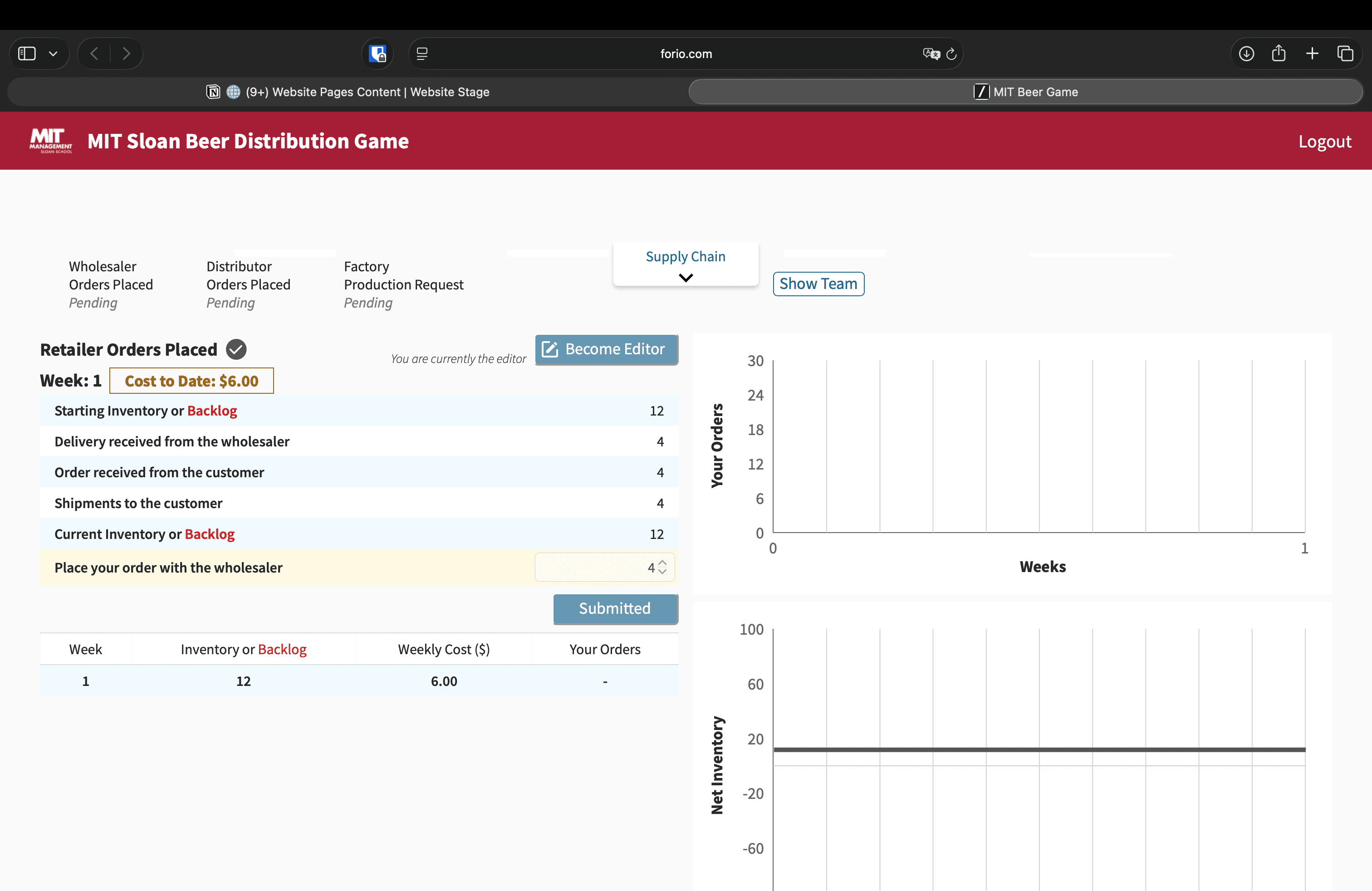

Participants step into one of these four roles—Retailer, Wholesaler, Distributor, or Factory—within a beer supply chain and must make weekly ordering decisions with limited information, strict communication boundaries, and rising time pressure.

No one can see end-customer demand except the retailer. No one can coordinate across roles. Every player is trying their best, but as the game unfolds, orders begin to spike, inventory swings wildly, and team chat fills with disbelief, blame, humor, and stress.

As the tension builds, participants begin forming theories about what must be happening at the customer end—most concluding there must be chaotic demand swings.

By the end, participants see clearly why complex systems routinely exhibit boom-and-bust cycles, massive amplification, finger-pointing, and costly coordination failures—insights they can immediately apply to real supply chain, organizational, and leadership challenges.

Core Competencies

Supply Chain Management

Systems Thinking

Decision Making Under Pressure

Learning Objectives

Resources to Power Your Simulation

This simulation comes with a Facilitation Guide along with 1:1 facilitator training and free trial accounts.

Available with this simulation

Facilitation Guide

Free Trial & Demo