Global Supply Chain

When Demand Shifts, Strategy Counts.

Simulation Overview

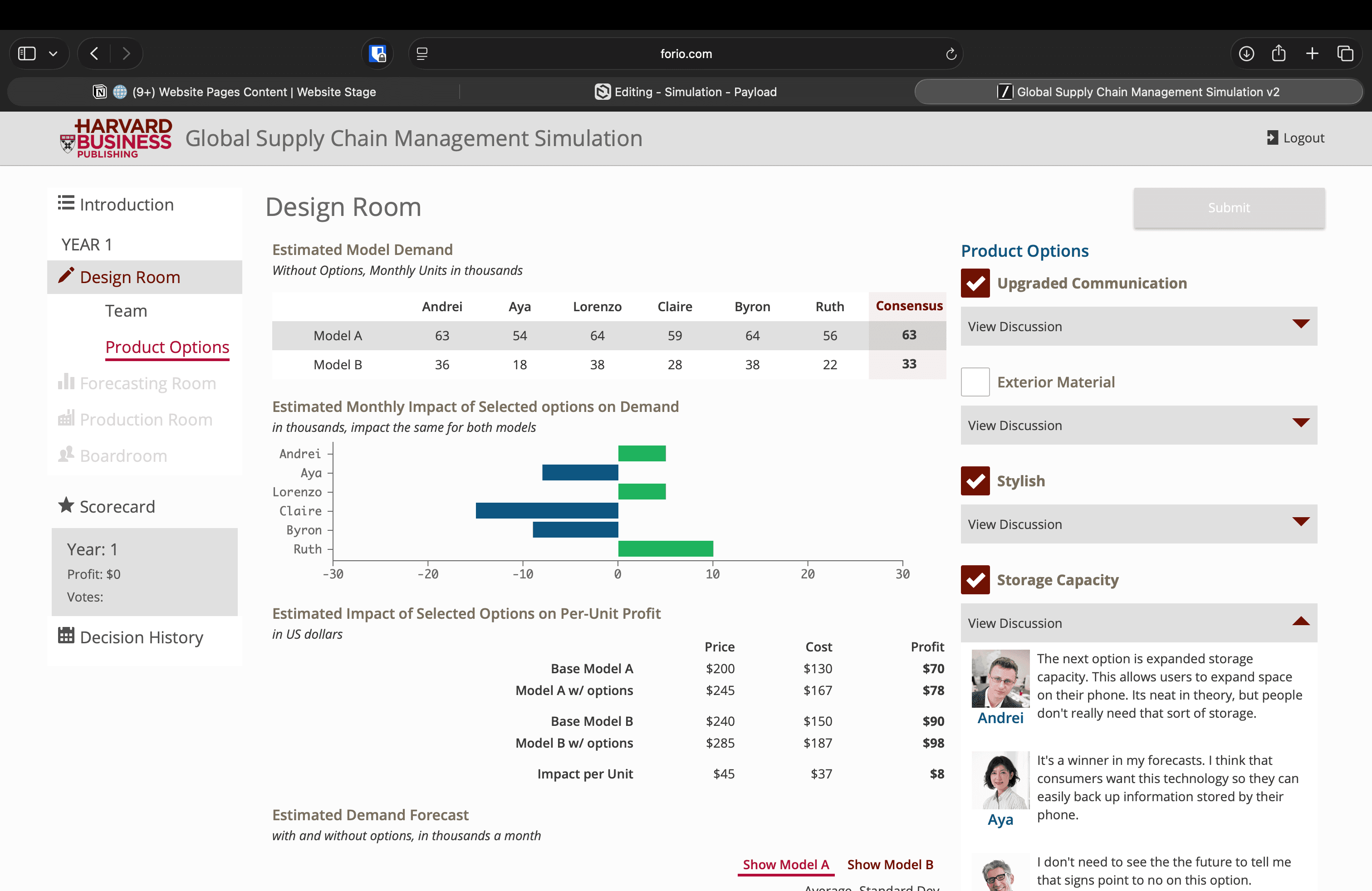

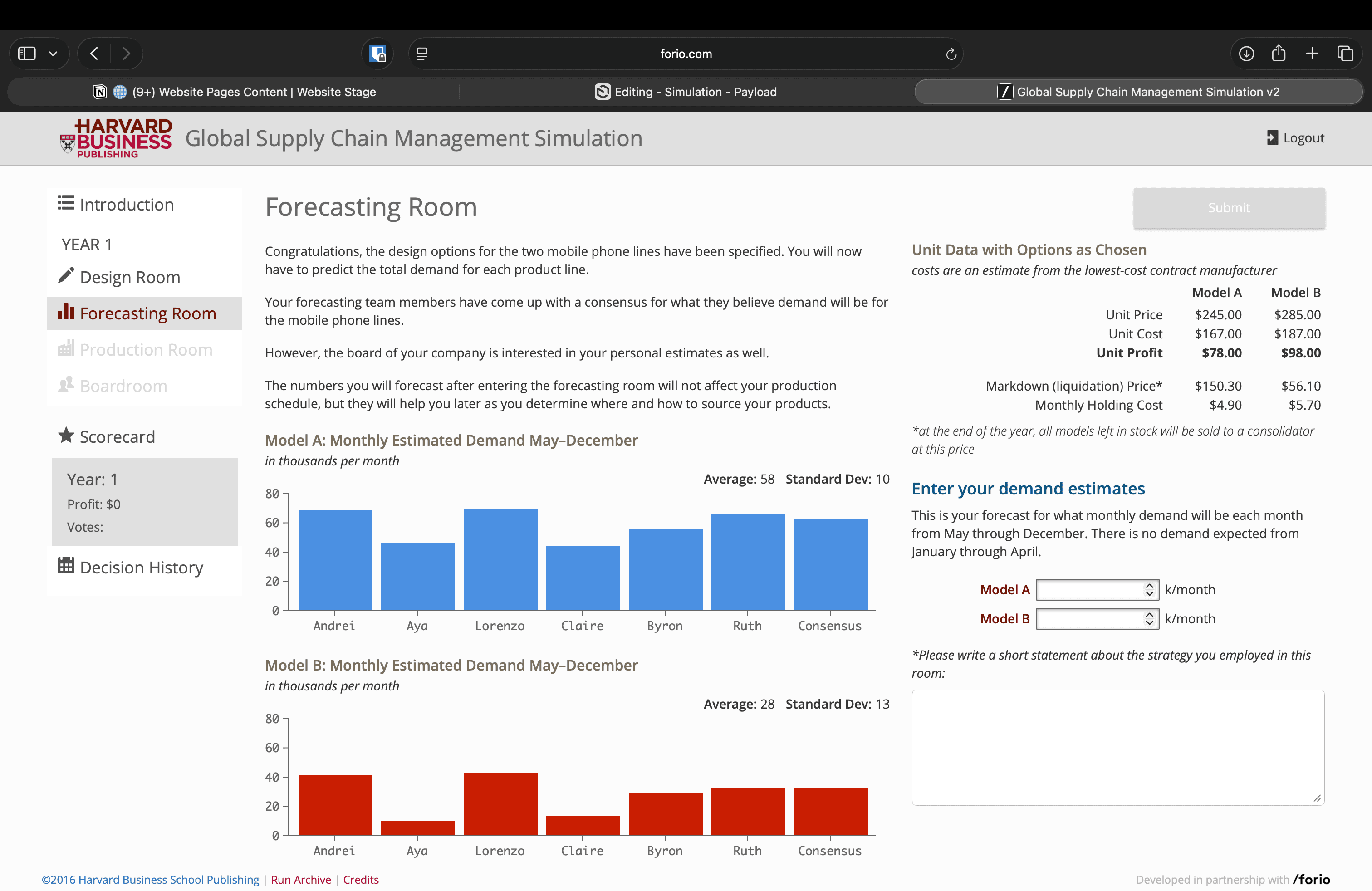

In the Global Supply Chain Management single-player asynchronous simulation from Harvard, participants are in charge of the supply chain for a global mobile phone manufacturer. They must design the product line, forecast demand, choose a set of suppliers, and allocate production among those suppliers.

Players

Single Player

Languages

English, Spanish, Portuguese, Chinese, Japanese

Simulation Time

Total Time: 2.25-3.75 hours

Intro 15 minutes, Gameplay 1-2 hours, Debrief 1-1.5 hours

Accessibility

WCAG 2.1 Compliance

Price

$165 per person

Simulation Categories

The Story

You work for a mobile phone company that has exploded onto the global scene with its sleek smartphones and a reputation for reliable performance at a fair price. The company has manufacturing partners on multiple continents, customers in dozens of countries, and a product team eager to launch a new generation of phones that will cement its place in a fiercely competitive market.

Step into the role of a global supply chain leader just as a new product season is about to start. Marketing is promising bold growth. Finance is cautious after a volatile year. Operations is warning that factories are already running near capacity. Meanwhile, a panel of internal “experts” offers wildly different demand forecasts: optimists see a blockbuster hit, pessimists predict a flat market, and the consensus forecast sits uncomfortably in the middle.

The simulation begins with a blank slate—and a deadline. Will your decisions make or break the performance of this global supply chain?

Core Competencies

Supply Chain Management

Systems Thinking

Measurement and Analysis

Learning Objectives

Resources to Power Your Simulation

This simulation comes with a Facilitation Guide along with 1:1 facilitator training and free trial accounts.

Available with this simulation

Facilitation Guide

Debrief Slides

Free Trial & Demo

Check Out Similar Forio Sims

Supply Chain and Capacity Planning

The Beer Game

The Beer Game is a supply chain management simulation that illustrates the bullwhip effect, demonstrating how small fluctuations in consumer demand can lead to amplified fluctuations in inventory and ordering throughout a supply chain.

Check It Out

Supply Chain and Capacity Planning

Coffee Trade

Negotiations around buyer-supplier contracts are critical to supply chain management, communication and coordination. In this team-based simulation, participants apply strategies for contract negotiation in a rapidly changing environment.

Check It Out

Operations Management

Benihana

Learners manage operations at Benihana, experimenting with batching, bar design, and service timing to optimize throughput, capacity utilization, and profitability in a dynamic restaurant environment.

Check It Out