Balancing Process Capacity

Simulating high-volume car wash operations

Simulation Overview

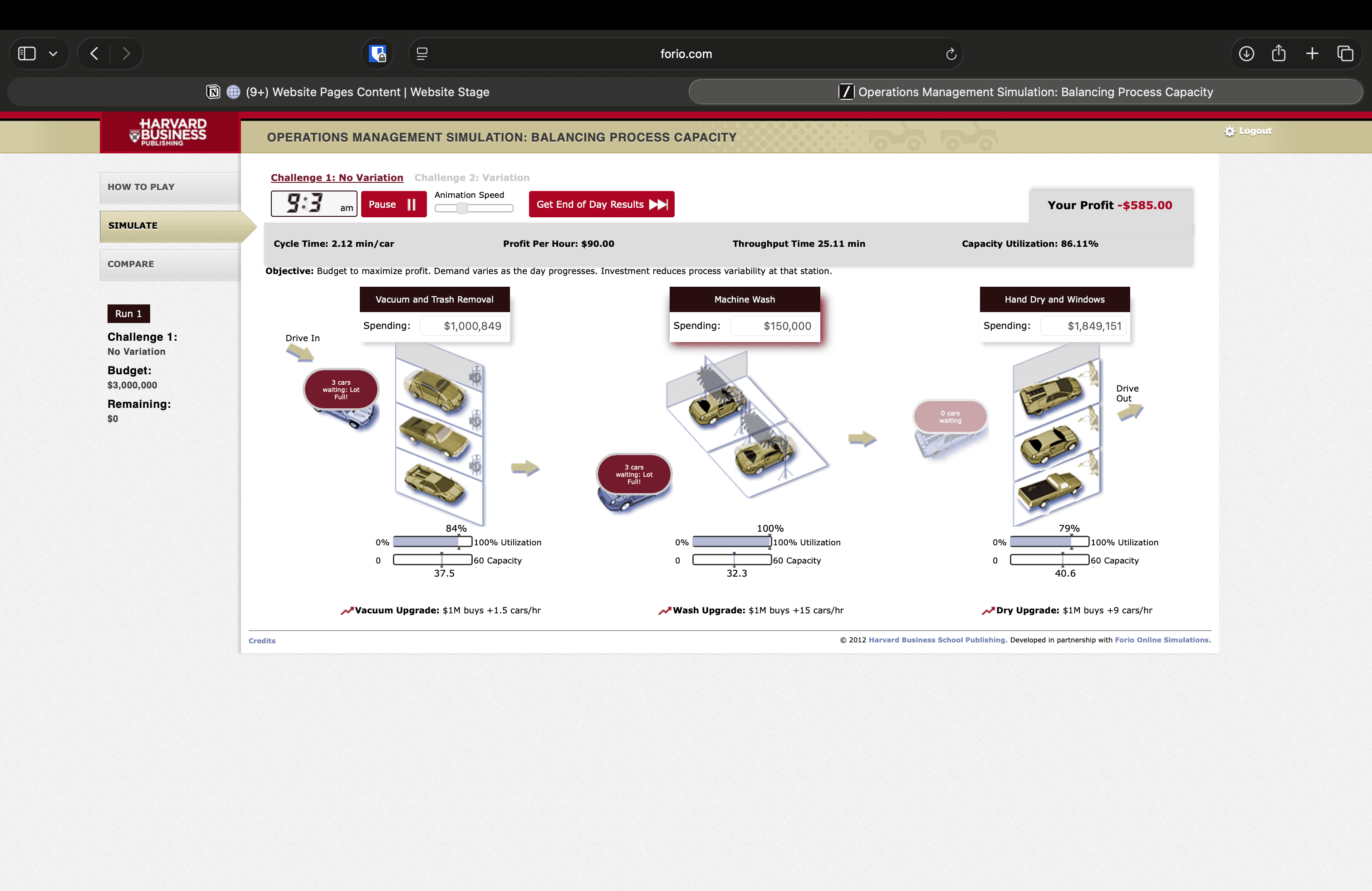

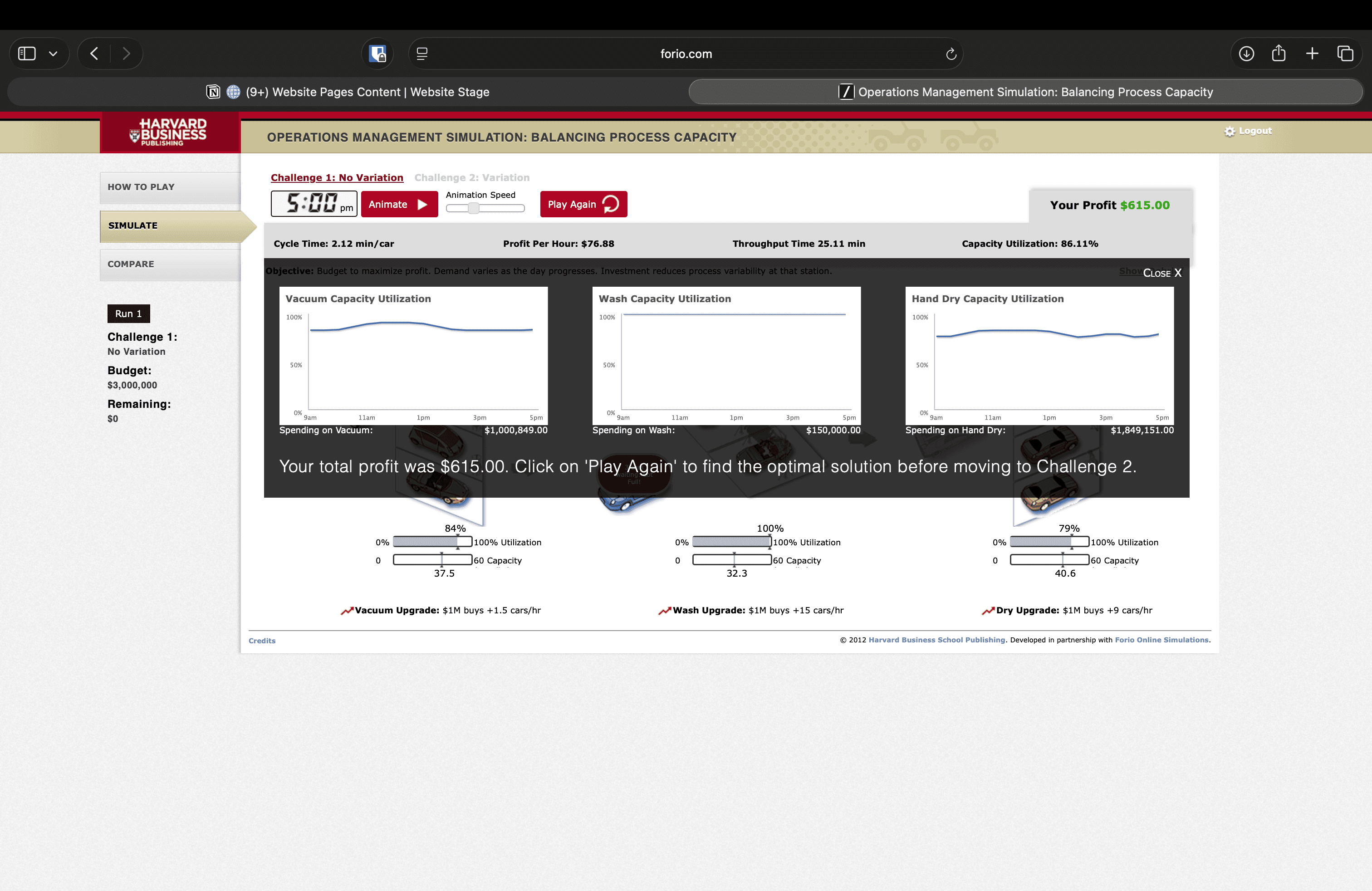

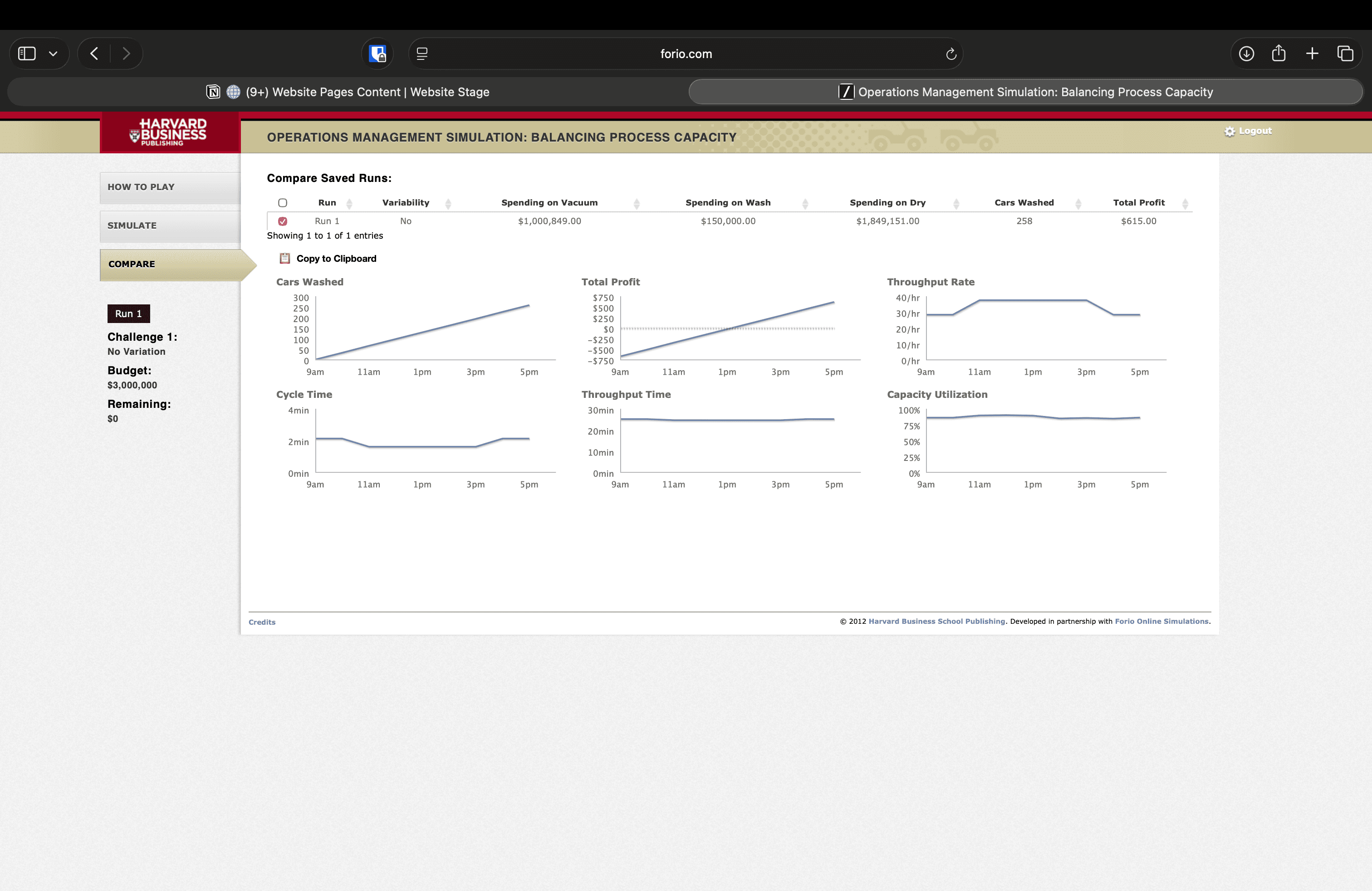

In this simulation, students optimize operations at a car wash by eliminating bottlenecks, managing variability, and maximizing efficiency across vacuum, wash, and hand-dry stations.

Players

Single Player

Languages

English

Simulation Time

Total Time: 1.5 hours

Intro 10 minutes, Gameplay 20 minutes, Debrief 1 hour

Accessibility

No Accessibility Compliance

Price

$165 per person

Simulation Categories

The Story

In this hands-on simulation, students take on the role of operations managers at a busy car wash, responsible for streamlining performance across three key areas: vacuum, machine wash, and hand-dry stations. Their mission is to eliminate process-related bottlenecks, boost resource utilization, reduce variability, and ultimately improve overall profitability. The simulation presents two configurable challenges—one with steady, predictable demand, and another where both demand and process times fluctuate. Through these scenarios, students learn to adapt their strategies, balance efficiency with flexibility, and make data-driven decisions to keep the car wash running smoothly.

Core Competencies

Operational Efficiency

Systems Thinking

Measurement and Analysis

Learning Objectives

Resources to Power Your Simulation

Each simulation comes with a Facilitation Guide along with 1:1 facilitator training and free trials.

Available with this simulation

Facilitation Guide

Free Trial & Demo

Check Out Similar Forio Sims

Operations Management

Balancing Process Capacity

Students are charged with eliminating process-related bottlenecks, maximizing utilization, reducing process variability, and improving profitability across three different sections of a car wash: vacuum, machine wash, and hand-dry stations. This exercise includes two configurable challenges. In some cases the demand is constant, and in other cases both the demand and the processes include variation.

Check It Out

Change Management

Power and Influence

A Harvard Business simulation, where the learners lead organizational transformation at a sunglasses manufacturing company as a change leader—build credibility, manage resistance, and use influence strategically to drive meaningful, lasting change.

Check It Out

Leadership and Teamwork

Breaking News

In the Innovation Simulation, you play the role of a Product Manager who is tasked with finding a strategy to help a struggling newspaper company. Working around time limits and budget, participants must design innovative campaigns, focus groups, and R&D projects.

Check It Out