System Utilization in Service Management

Operations Management Exercise

Operations Management Exercise

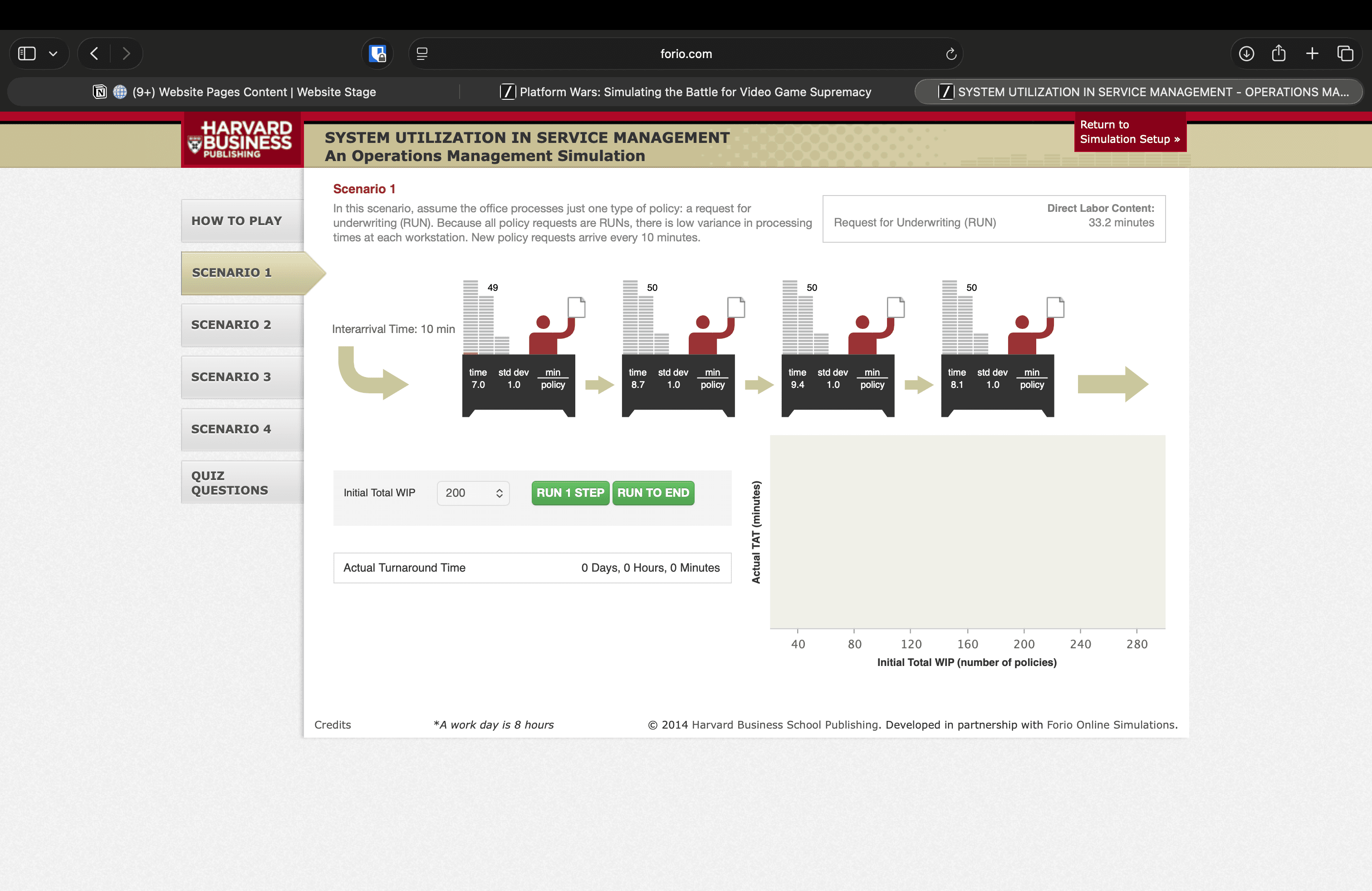

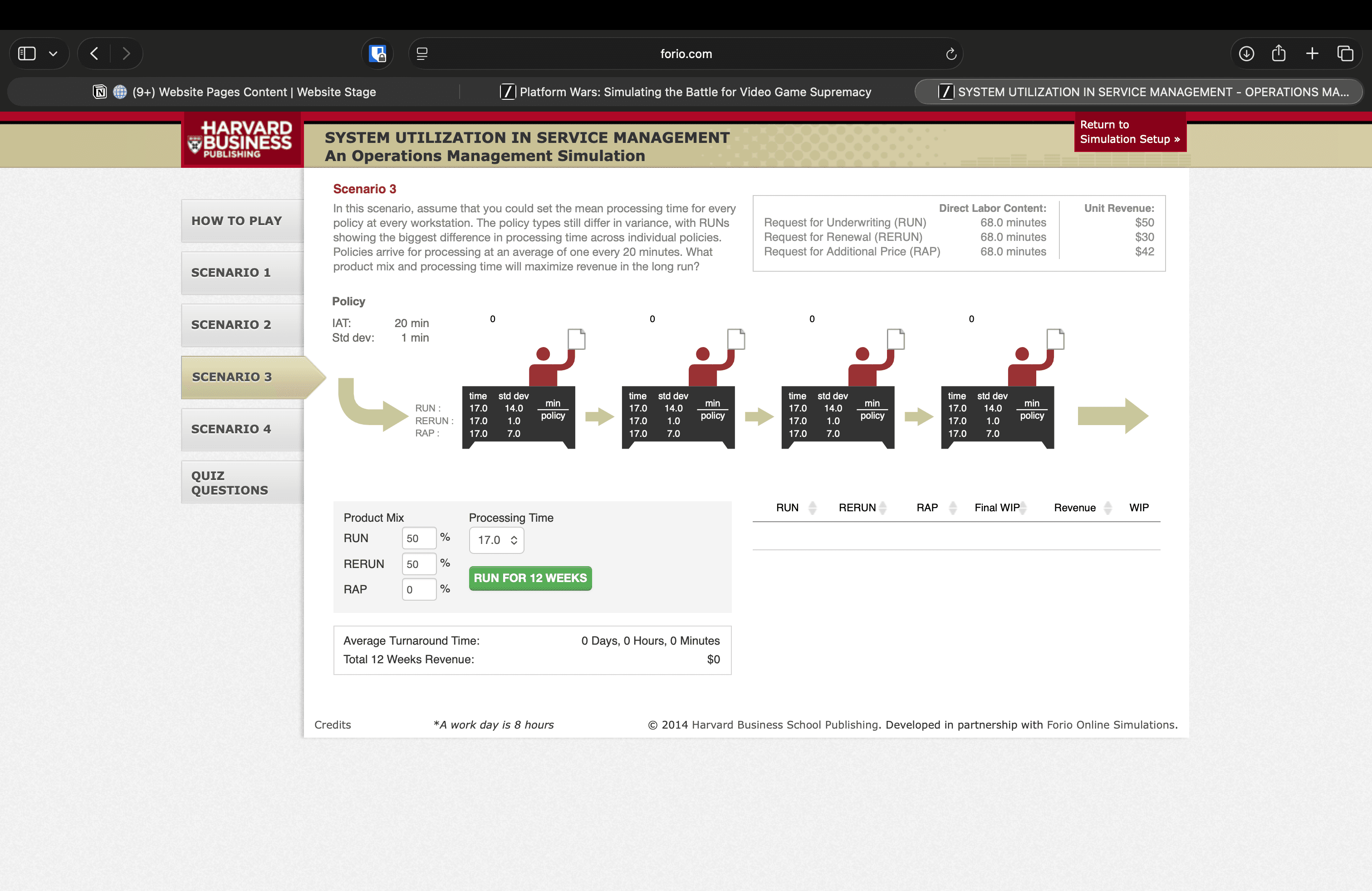

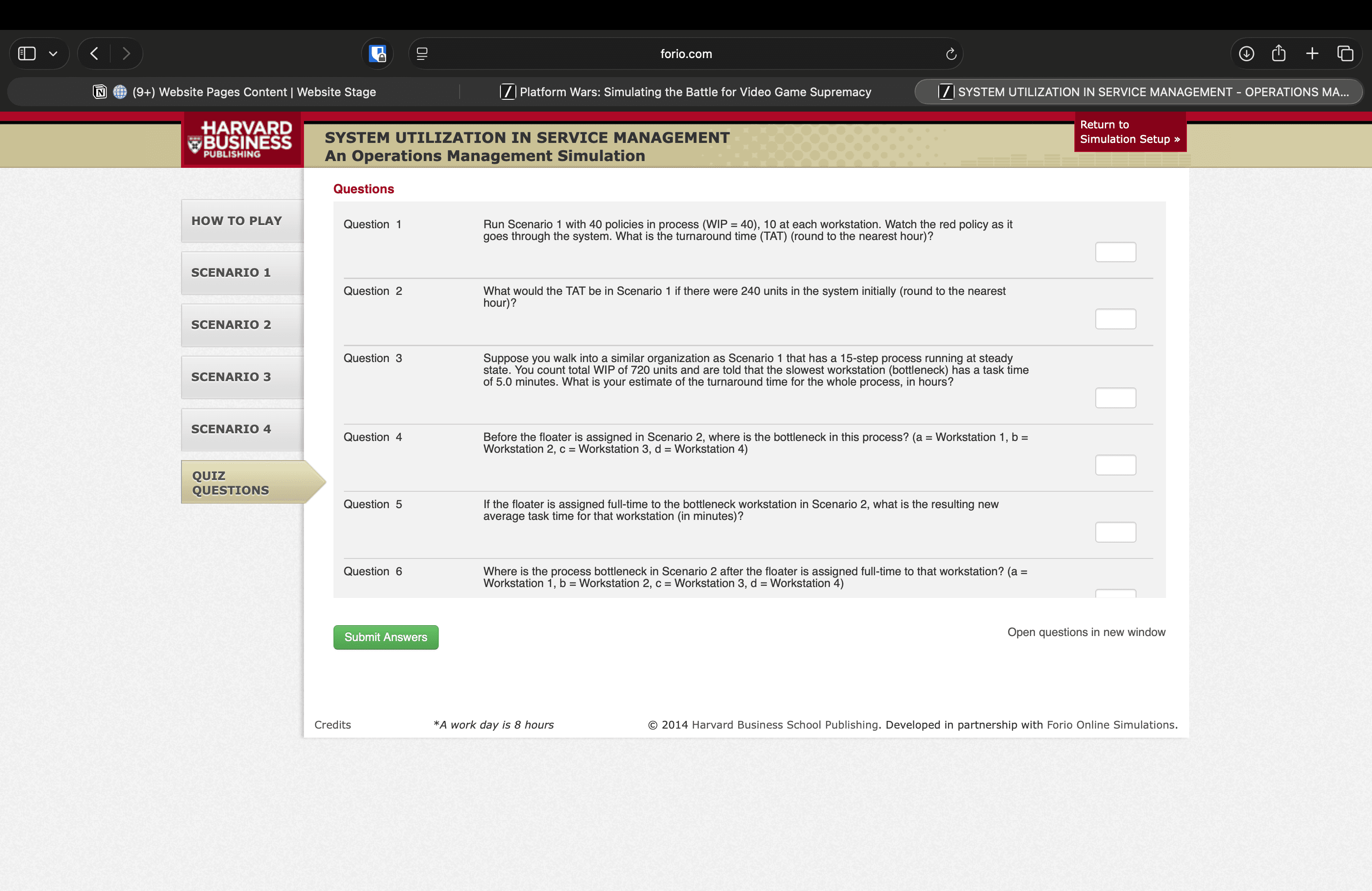

Learners manage a service operation that processes insurance policies, balancing flow, capacity, and demand variability across multiple workstations. Through four configurable scenarios, they explore how process design and utilization affect turnaround time, work-in-process, and overall system performance. The simulation brings foundational operations principles—such as Little’s Law and bottleneck analysis—to life through hands-on experimentation and data-driven decision-making. An integrated assessment reinforces key concepts and supports debrief discussion.

Players

Single Player

Languages

English

Simulation Time

Total Time: 40-60 minutes

Intro 5-10 minutes, Gameplay 15-20 minutes, Debrief 20-30 minutes

Accessibility

No Accessibility Compliance

Price

$165 per person

Simulation Categories

The Story

Learners step into the role of a service operations manager at an insurance firm facing delays and customer complaints. Their task is to diagnose the process—tracking policies as they move through multiple workstations—and test changes to improve turnaround time and output. As the scenarios progress, they experiment with staffing, capacity balancing, and product mix decisions to stabilize performance and prevent the system from collapsing under excess demand. Each decision reveals the tension between efficiency, variability, and responsiveness in real-world operations

Core Competencies

Operational Efficiency

Critical Thinking and Problem Solving

Decision Making Under Pressure

Systems Thinking

Measurement and Analysis

Learning Objectives

Resources to Power Your Simulation

This simulation comes with a Facilitation Guide along with 1:1 facilitator training and free trials.

Available with this simulation

Facilitation Guide

Free Trial & Demo

Check Out Similar Forio Sims

Operations Management

Balancing Process Capacity

Students are charged with eliminating process-related bottlenecks, maximizing utilization, reducing process variability, and improving profitability across three different sections of a car wash: vacuum, machine wash, and hand-dry stations. This exercise includes two configurable challenges. In some cases the demand is constant, and in other cases both the demand and the processes include variation.

Check It Out

Supply Chain and Capacity Planning

Push v. Pull

Manage a computer production facility using Push and Pull methods, exploring impacts on demand, inventory, and capacity. Includes six configurable scenarios and a built-in assessment quiz.

Check It Out

Operations Management

Multiple-Server Queues

In this single-player asynchronous game, the participants manage several configurations of a hospital Intensive Care Unit (ICU), including multiple specialized units or a larger pooled unit. Variability in arrival times, service times, and resource utilization are configurable, and all impact patient waiting times. The exercise illustrates trade-offs between cost, patient experience, and clinical quality in queuing systems. This exercise includes two configurable scenarios and an assessment quiz built in to the exercise.

Check It Out

Operations Management

Inventory Basics

Manage inventory for a hardware store across 12 weeks, balancing costs and demand. Features three configurable scenarios and a built-in quiz to reinforce key inventory management concepts.

Check It Out

Operations Management

Benihana

Learners manage operations at Benihana, experimenting with batching, bar design, and service timing to optimize throughput, capacity utilization, and profitability in a dynamic restaurant environment.

Check It Out